Damage Evolution Simulations

page information

Writer InssTek 작성일23-04-17 19:40related link

-

https://lnkd.in/gD7ndHWV

485 times connection

https://lnkd.in/gD7ndHWV

485 times connection

body text

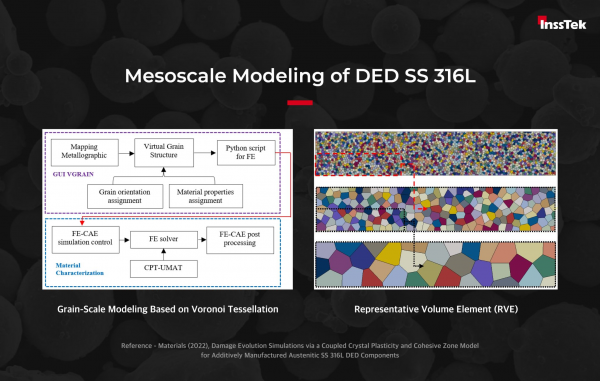

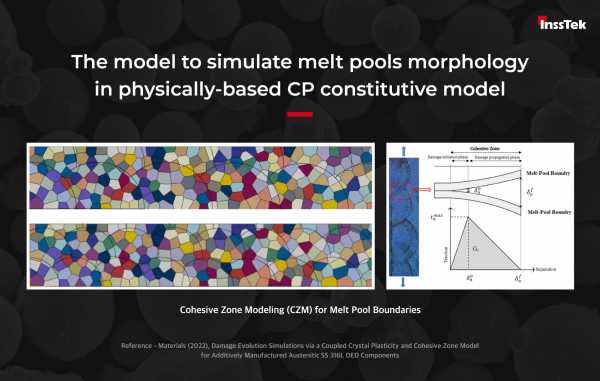

“Damage Evolution Simulations via a Coupled Crystal Plasticity and Cohesive Zone Model for Additively Manufactured Austenitic SS 316L DED Components – Metals 2022”

- Highlights

• This study represents damage simulation for SS316L using DED additive manufacturing using InssTek's DMT Technology.

• Regarding the impact of the number of melt pools on the tensile properties, melt pool size controlling can be prone as a significant way to achieve the required features.

• The proposed methodology is expected to yield satisfactory outcomes in dealing with the grain morphology and melt pool size effects on the mechanical behavior, and it is believed that it will provide complementary insights into the material design concept and pave the way for the broader use of DED in the industry.

Reference: Metals is an international, peer-reviewed, open access journal published monthly online by MDPI.

- Highlights

• This study represents damage simulation for SS316L using DED additive manufacturing using InssTek's DMT Technology.

• Regarding the impact of the number of melt pools on the tensile properties, melt pool size controlling can be prone as a significant way to achieve the required features.

• The proposed methodology is expected to yield satisfactory outcomes in dealing with the grain morphology and melt pool size effects on the mechanical behavior, and it is believed that it will provide complementary insights into the material design concept and pave the way for the broader use of DED in the industry.

Reference: Metals is an international, peer-reviewed, open access journal published monthly online by MDPI.

Comments list

No comments have been registered.