Event

Upcoming Events

IMTS 2022

WE CAN'T WAIT TO SEE YOU!

The International Manufacturing Technology Show, the largest and longest-running industry trade show in the Western Hemisphere, is held every other year at McCormick Place in Chicago, Illinois. IMTS 2022, which will run September 12-17, 2022, is where the creators, the builders, the sellers, and the drivers of manufacturing technology come to connect and be inspired.

You are welcome to visit our stands and experience INSSTEK’s newly released product line!

✔️Products

- MX-Lab, MX-Fab

✔️Zone

- Aerospace, Medical, NEW Project (NARAE)

✔️Core Tech (Function Features)

- DMT Technology, NEW Module, CVM Powder Feeding System, 5axis-AM CAM

✔️Application

- Rocket Nozzle, Multi-Material, Porous Coating (FDA approved), and various 5-Axis Samples

ICAM(ESA) Online Event

“We invite you to the conference is discussion and exchange of experience!"

InssTek will be a presentation at the 1st ICAM(International Conference on Advanced Manufacturing)

for air, space, and land transportation co-hosted by ESA & NASA.

[Session]

- 14:00(CET) Thursday 10 March 2022

- Room C: Additive Manufacturing – Process Development III

“Multi Material Rocket Nozzle Manufacturing Process

– From Material Research to Fabrication with Direct Energy Deposition(DED)”

We look forward to your participation :)

Sygnis S.A. Online Webinar

"Meet InssTek in the webinar about the application of additive technology!"

Sygnis S.A. invites you to our regular workshops on new technologies in the form of webinars.

In this workshop, you will learn how to apply additive technology in theory and practice.

◆ The organizer of the webinar: Sygnis S.A.

◆ Friday, February 25, 2022 - 1:00 PM

◆ "Multi-material manufacturing" - from material research to industrial applications using DED technology.

This webinar will present new proprietary material testing methods developed by InssTek and real-world industrial applications in multi-material manufacturing.

From material research to industrial applications, you can take a closer look at several processes.

We look forward to your interest and expectations :)

NiCoMoTiAl High Entropy Alloying in DED/…

High Entropy Alloys (HEAs) is attracting attention as a novel material to be used in various industrial fields with its excellent physical properties that can adapt to extreme environments. Especially in aerospace and the energy industry, the requirement for alloys maintaining properties at high temperature environments is increasing, and HEAs are being studied intensively to solve its. In this study, NiCoMoTiAl HEA with γ/γ' microstructure which can secure high temperature characteristics is alloyed through DED/AM technology, and a new “Rapid Alloy Scanning” methodology using the CVM Powder Feeding System is suggested. Each of the five elements comprising the alloy is manufactured from pure metal powders, with DED/AM technology in various combinations. This allows the rapid design of the proper portion of elements. NiCoMoTiAl HEA produced via DED/AM with optimal content has been observed region and stable FCC structure through SEM/EDS/XRD analysis. After heat treatment at 1,250℃, the γ/γ' microstructure was identified, and it has been demonstrated that the alloy has superior lattice parameter and solvus temperature than previously studied alloys. The methods used in this experiment are expected to overcome the physical limitations of conventional alloy design methods and present novel methodological paradigms of FGMs, MMCs, and HEAs studies.

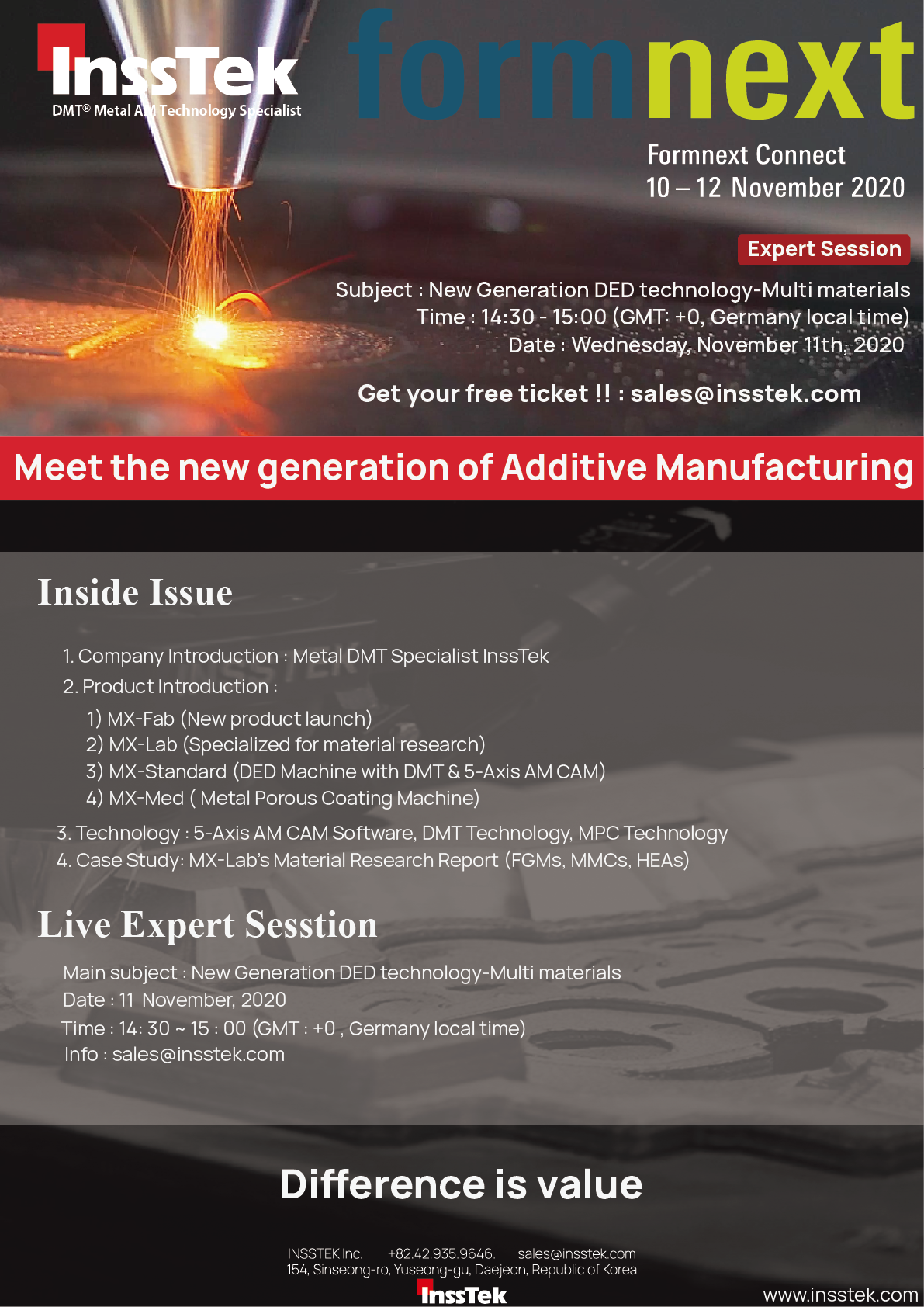

Formnext Connect 2020

InssTek will participate FORMNEXT CONNECT 2020.

In 2020 Formnext Connect is the virtual alternative for business and knowledge exchange for the global AM community

in these times of a global pandemic. InssTek, Inc. will introduce InssTek’s accumulated 3D metal printing technology

as DED(Direct Energy Deposition) method and new products line-up

Especially, InssTek will provide Expert Live Session" on Wednesday, November 11th 2020.

If you need free visitor ticket, Please send e-mail to sales@insstek.com

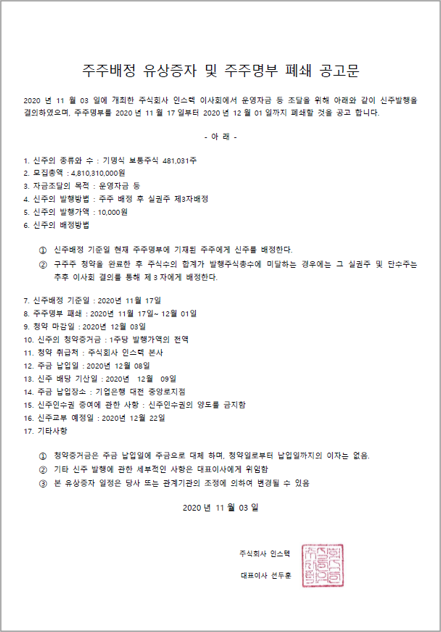

주주배정 유상증자 및 주주명부 폐쇄 공고문 (2020.11.03)

2020년 11월 03일에 개최한 주식회사 인스텍 이사회에서 운영자금 등 조달을 위해 아래와 같이 신주발행을 결의하였으며,

주주명부를 2020년 11월 17일부터 2020년 12월 01일까지 폐쇄 할 것을 공고 합니다.

World Manufacturing Japan 2020 (26-28 Fe…

Launched more than 30 years ago, Manufacturing World Japan has grown together

with the Japanese & Asian manufacturing industry. Gathering all kinds of cutting edge

mechanical components/manufacturing services/IT solutions for any types of manufacturing

industry from around the world. The show consists of the following 8 shows.

InssTek, Inc will participate this "World Manufacturing Japan 2020" exhibision and

share inssTek's accmulated technologies and New generation model MX-Lab.

https://www.japan-mfg.jp/en-gb.html

formnext 2017

formnext powered by tct is the leading tradefair for Additive Manufacturing and the next generation of intelligent manufacturing solutions. It focuses on the efficient realization of parts and products, from their design to serial production. formnext shows the future of innovative manufacturing.

InssTek will attend the DMT® Desktop Metal 3D Printer and metal 3D printed sample from InssTek, Inc.

The fair will be held at Messe Frankfurt, 60327, Germanyfrom 14th to 17th November 2017.

https://www.mesago.de/en/formnext/home.htm