Case Study.17_Multi-Material Research[AlBronze+IN718]

page information

Writer InssTek 작성일21-10-26 10:33related link

body text

“Multi-Material (Al Bronze + IN718) test with MX-Lab”

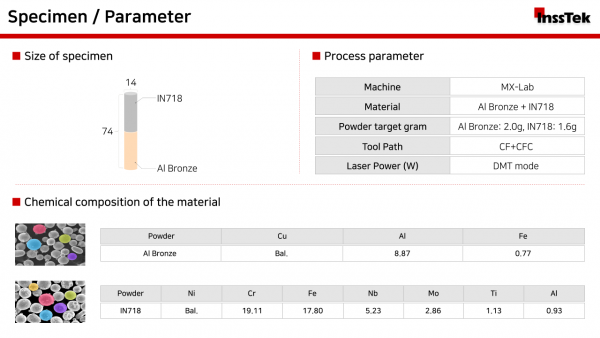

In this case study, a multi-material sample of Ni-based alloy and Copper-based alloy was manufactured by 3D printing (MX-Lab), and mechanical properties were tested to confirm the possibility of using multi-material of both materials.

Al Bronze + IN718 multi-material specimens could be easily manufactured using the MX-Lab.

Ni-based alloy is widely used in extreme environments such as aerospace, power generation, and the oil & gas industry.

However, the restricted thermal conductivity constrains the application of Ni-based alloys in high heat flux cases.

The joining of materials with high thermal conductivity such as copper alloy to Ni-based alloys can improve upon this limitation to adapt for temperature-sensitive requirements.

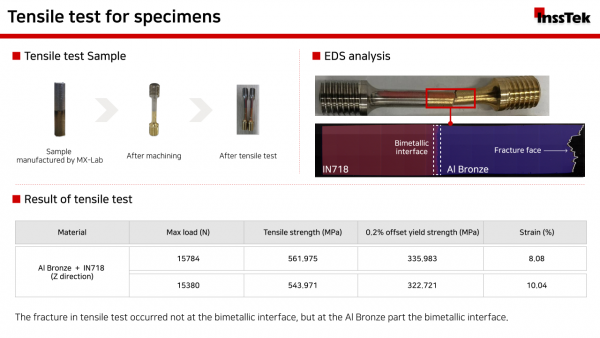

The specimens were subjected to a tensile test according to ASTM E8 after machining.

As a result of the tensile test for specimens, no fracture occurred at the bonding interface.

The fracture was occurred in the Al Bronze part because of the lower tensile strength of Al Bronze than IN718.

In this case study, a multi-material sample of Ni-based alloy and Copper-based alloy was manufactured by 3D printing (MX-Lab), and mechanical properties were tested to confirm the possibility of using multi-material of both materials.

Al Bronze + IN718 multi-material specimens could be easily manufactured using the MX-Lab.

Ni-based alloy is widely used in extreme environments such as aerospace, power generation, and the oil & gas industry.

However, the restricted thermal conductivity constrains the application of Ni-based alloys in high heat flux cases.

The joining of materials with high thermal conductivity such as copper alloy to Ni-based alloys can improve upon this limitation to adapt for temperature-sensitive requirements.

The specimens were subjected to a tensile test according to ASTM E8 after machining.

As a result of the tensile test for specimens, no fracture occurred at the bonding interface.

The fracture was occurred in the Al Bronze part because of the lower tensile strength of Al Bronze than IN718.

Comments list

No comments have been registered.