Wear behavior of aluminum-matrix particle (TiH2 and ZrH2)

page information

Writer InssTek 작성일23-07-03 17:20related link

-

https://www.linkedin.com/feed/update/urn:li:activity:70815389110883573…

652 times connection

https://www.linkedin.com/feed/update/urn:li:activity:70815389110883573…

652 times connection

body text

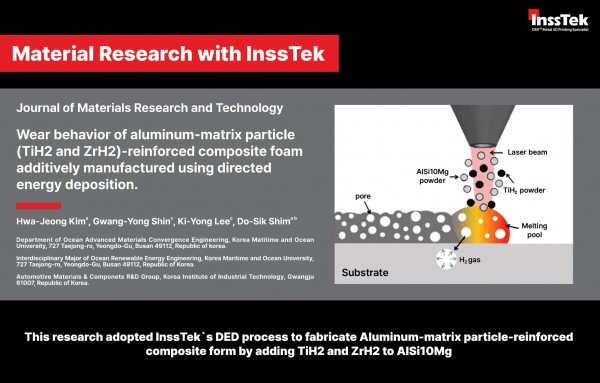

“Wear behavior of aluminum-matrix particle (TiH2 and ZrH2)-reinforced composite foam additively manufactured using directed energy deposition – Journal of Materials Research and Technology 25(2023)”

- Highlights

• This research adopted InssTek`s DED process to fabricate aluminum-matrix particle-reinforced composite form by

adding TiH2 and ZrH2 to AlSi10Mg.

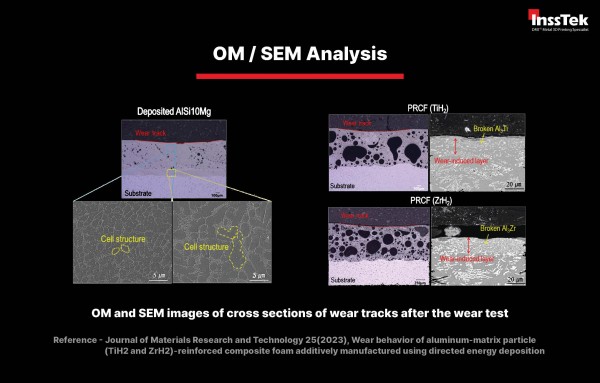

• Owing to the intermetallic compound formed upon the reaction between AlSi10Mg and foaming agent,

only a part of the aluminum matrix was removed due to wearing.

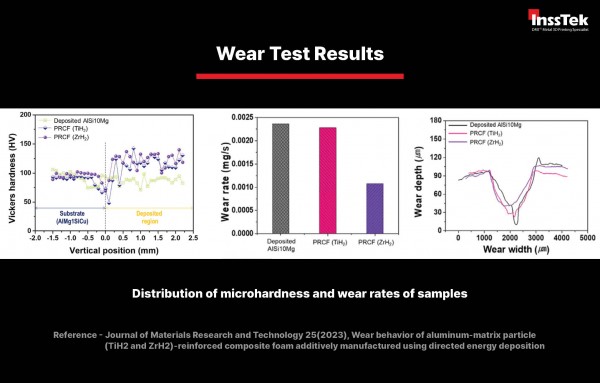

• Wear test results showed that the deposited AlSi10Mg fabricated with ZrH2 had the best wear resistance.

- Highlights

• This research adopted InssTek`s DED process to fabricate aluminum-matrix particle-reinforced composite form by

adding TiH2 and ZrH2 to AlSi10Mg.

• Owing to the intermetallic compound formed upon the reaction between AlSi10Mg and foaming agent,

only a part of the aluminum matrix was removed due to wearing.

• Wear test results showed that the deposited AlSi10Mg fabricated with ZrH2 had the best wear resistance.

Comments list

No comments have been registered.